HARD-BOILED HAUL

Our prepared egg snacks are good to go whenever you are. Get a step-by-step walkthrough of our hard-boiled egg process here.

Eggs from Farms

Half of our eggs are produced right here on our farm, while the other half come from trusted local family farms we partner with. Together, they help us maintain a consistent supply of fresh, high-quality eggs—every single day. To ensure traceability and peak freshness, we track each egg from the time it’s laid all the way through processing.

STEP

01

STEP

02

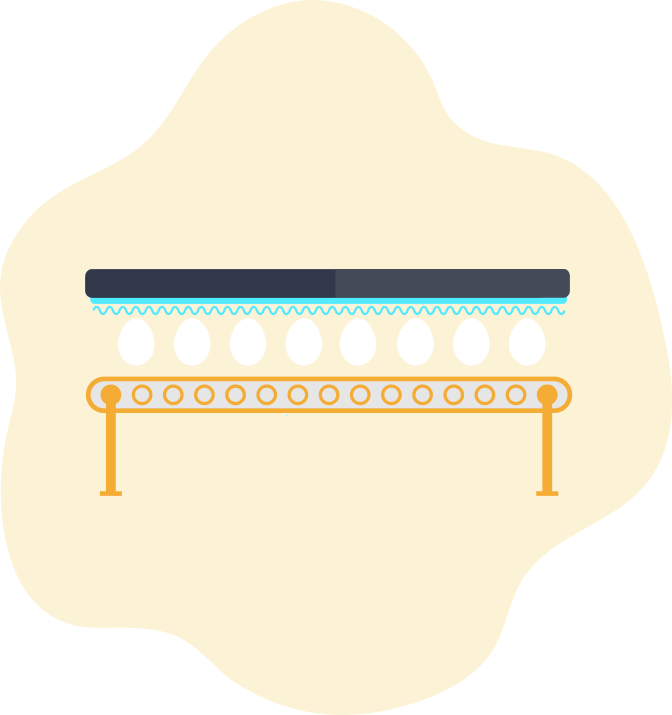

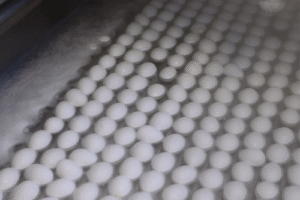

Egg Loading

The grading process begins as flats of eggs are gently lifted onto a moving conveyor using soft suction cups, ensuring each egg is handled with care.

View Gallery

Candling

After cleaning, the eggs undergo candling—an inspection method where they are passed over high-intensity lights that illuminate the interior. This allows trained personnel to detect shell cracks, internal defects such as blood spots, and overall egg quality. Only eggs that meet strict grading standards proceed to the next stage.

View Gallery

STEP

03

STEP

04

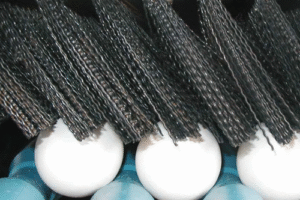

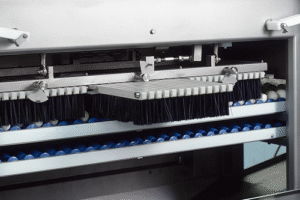

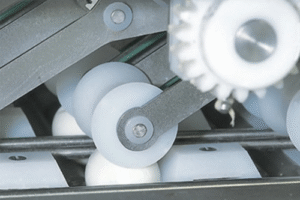

Cleaning Eggs

Throughout the grading process, eggs are gently tapped using precision pegs that measure acoustic response. By analysing the frequency and resonance of each tap, the system can detect hairline cracks or structural weaknesses in the shell—ensuring only intact eggs continue down the line.

View Gallery

UV Sterilization

The eggs are gently cleaned using rotating brushes designed to remove dust and surface particles — ensuring cleanliness while maintaining shell integrity.

View Gallery

STEP

05

STEP

06

Conditioning

In this stage, eggs are exposed to controlled ultraviolet (UV) light as they pass through a specialized chamber. The UV rays effectively eliminate the surface bacteria and pathogens, providing an added layer of food safety without impacting the egg’s quality.

View Gallery

Boiling

Eggs are precisely sorted by shell size and weight to meet grading requirements. Once classified, they move on to packaging lines tailored to their specific size category.

View Gallery

STEP

07

STEP

08

De-shelling & Defect detection

Once graded, eggs are precisely packed into cartons or fibre flats—securely contained and ready for distribution, with quality and freshness preserved at every step.

View Gallery

Packaging

Eggs are precisely sorted by shell size and weight to meet grading requirements. Once classified, they move on to packaging lines tailored to their specific size category.

STEP

09